Otto’s Motor

First a little history. Back in the middle of the 19th

Century a traveling salesman named Nicolaus Otto was reading about the new

invention of the Lenoir gas powered motor. His sales area was

all of western Germany and most of the traveling he did was by horse drawn

coaches. Otto was a fastidious man and he was repelled by the thousands

of tons of horse manure on the roads everywhere. He had a

dream of developing a motor which could be fueled by liquid fuel like gasoline

and small and powerful enough to propel a road vehicle. The

Lenoir motor ran on town gas and was big, heavy, and stationary.

Otto started working on the development of a small motor

as a hobby project while he continued his trade of traveling and selling

coffee, tea, and sugar.

His

first experiments ended with the test motor destroying

itself. He pressed on and after years of work came up with a

motor based loosely on the two stroke gas motor of

Lenoir. He showed his work to a friend who was in the

sugar factory business and from him got the funding to start a motor company.

While manufacturing big stationary gas motors he continued his dream project of

a small, light, and powerful gasoline motor.. The town gas

motors they made were free piston atmospheric motors standing 10 feet tall and

weighing over a ton. I prefer to not include a picture of the

wretched thing. And they were limited to about 3 horsepower.

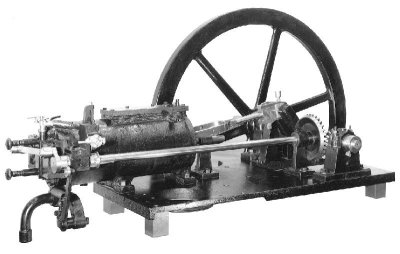

Otto’s company hiring Gottlieb Daimler and then Daimler bringing Wilhelm Maybach aboard was the magic ingredient that made the 1876 4-stroke New Otto motor possible..

If you look close you can see the exhaust valve is operated by a roller cam..

From my research I am convinced that it was the mechanical

genius of Maybach combined with the organization of Daimler both pushed by the

drive and ambition of Otto which made the modern 4 stroke motor invention

possible.

Daimler

and Maybach left Otto’s company within a few years and started their own

experiments in the greenhouse on Daimler’s estate..

They were so secretive about their work that the gardener became convinced that

they were counterfeiting money in their secret workshop.. The

police were called and found nothing but machine tools and motor

parts.. I wonder what became of the gardener?

The

Maybach-Daimler high speed gasoline motor became wildly successful.

Most of the early development of motor vehicles was done with motors either

purchased from or built under license from Daimler..

Panhard and Levassor in France and Henry Ford in the United States are a few of

the users of the Maybach-Daimler motors..

Otto

spent most of his time and energy fighting with the German government about his

patent rights. Some say that it exhausted him to the point of

causing his premature death at only 59 years old.. And

old Lenoir in Paris also wound up with little to show for his efforts..

He died in poverty..

After

Daimler’s death his company merged with Karl Benz’s operation and Maybach

continued his fine work.. He was the one towering talent who

made the Mercedes Benz possible. I am sure that

without Maybach that Benz would have wound up like Otto and Lenoir..

Now for some technical talk. I have been going on

about the history of the 4-stroke cycle gasoline motor without telling what it

is..

The simple explanation found everywhere (sometimes with

animations) is as follows.

Each movement of the piston from the bottom of the bore to

the top or from the top of the bore to the bottom is called a

stroke. The intake and exhaust valves open or shut at the end of

each stroke.

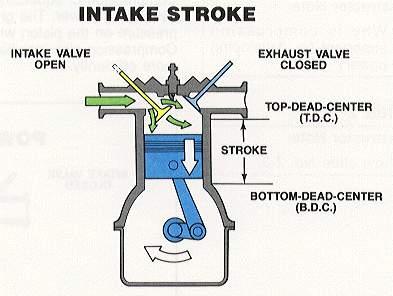

There are four strokes in one complete cycle of the motor.

1)

Intake

Stroke

(intake valve open)

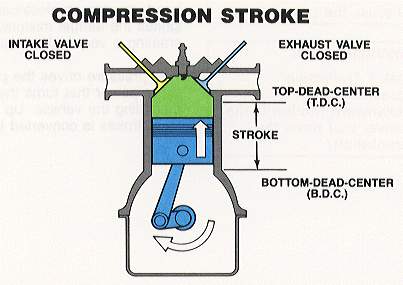

2)

Compression Stroke (both valves

closed)

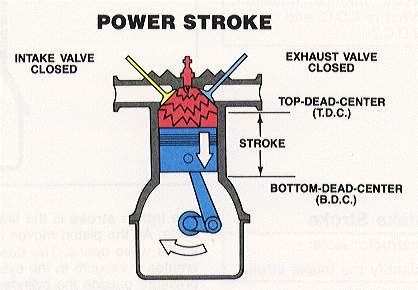

3) Power

Stroke

(both valves closed)

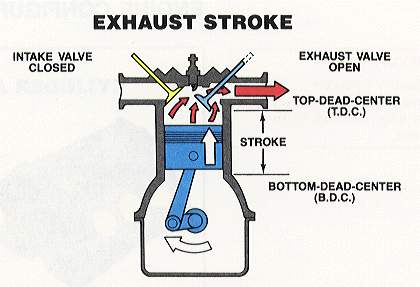

4)

Exhaust

Stroke

(exhaust valve open)

During the intake stroke the piston goes down and creates

a partial vacuum in the cylinder. The intake valve is open so the

fuel-air mixture in the intake manifold is pushed into the cylinder by the

pressure of the atmosphere.

During the compression stroke the piston goes up

compressing the fuel-air mixture. Both the intake and exhaust valves are

closed.

The compressed fuel-air mixture is ignited by a spark and

the burning mixture generates pressure which pushes the piston down briskly.

This is the power stroke. The intake and exhaust valves are

closed during this stroke also.

Then the piston comes back up on the exhaust stroke with

the exhaust valve open forcing the spent gases out of the cylinder.

Then during the next intake stroke the piston goes down

and creates a partial vacuum in the cylinder. The intake valve is

open so the fuel-air mixture in the intake manifold is pushed into the cylinder

by the pressure of the atmosphere.

And so forth and so on until you run out of gasoline or

turn it off..

Pretty simple, right? Well, maybe for

Otto’s original 4 stroke motor which made 3 horsepower at 180rpm..

What really happens is another story.

The

problem is that the air-fuel mixture has weight and inertia and in a modern

high speed motor the simplicity is lost because of that simple fact of

nature. At 6000rpm the four strokes of a motor takes only 1/50th

of a second.. Not very long.

Using the Dyno2000 program I entered a bogus cam which opens and closes the valves at top dead center and bottom dead center like in the ideal 4 stroke motor explained above. Also in the chart are the curves for a real motor (“Goody” a modified Chevrolet 350 V8 I built) As you can see the ideal cam timing leaves a little to be desired.

The only

difference between the motors in the curves is the cam timing.

Back to the reality of the operation of a modern 4 stroke

motor.

The intake valve opens during the last part of the exhaust

stroke (the exhaust valve is still open and the time that they are both open is

called the overlap period) Then during the first part of the intake

stroke the exhaust valve is still open.. Due to the inertia

of the exhaust gases leaving there is a lower pressure in the exhaust port and

some of the intake charge goes out into the exhaust port directly scavenging

the remnants of exhaust gases in the combustion chamber. (one

of the reasons a cam with lots of overlap gives lousy mileage) The piston

continues down on the intake stroke and then starts back up.

Then even though the piston is moving up on the

compression stroke the intake valve stays open. There is a small

pulse of positive pressure sent back into the intake manifold and causes a

spray of fuel (called stand off) out of the carburetor on some motors with wild

cams and short intake tracts. Then the intake valve finally closes

and the mixture is compressed by the piston coming up. Considerably

before the piston gets to the top of the compression stroke the spark plug is

fired and the burning of the mixture starts.. The piston is still

coming up and it is a race between the fire and the aluminum to see who

wins. If the fire wins (due to the mixture burning too fast)

you can get detonation leading to much heartache..

Then the

piston starts back down on the power stroke.. The pressures

involved are high (up to 1000lbs per square inch) and this is what makes the

twisting force on the crankshaft called torque. Long before

the piston reaches the bottom of the cylinder the exhaust valve

opens.. (this is what makes the more aggressive cams so loud)

Then the

piston is on the way up with the hot exhaust gases flowing out of the exhaust

ports. Before the piston is to the top the intake valve opens with

the exhaust valve still open.. And I think this

is where we came in to this picture...

So there

you have it.. Not simple and mostly designed many years ago

by good mechanics and engineers trying different things and seeing what worked..

I leave you with a quotation from Gottlieb Daimler (from

the time when he and Maybach were working in the garden workshop..

“Let’s start her up and see why she don’t run!”

Rick Draganowski

Gold Beach, Oregon USA